¿Por qué elegir cartón kraft revestido para sus necesidades de embalaje?

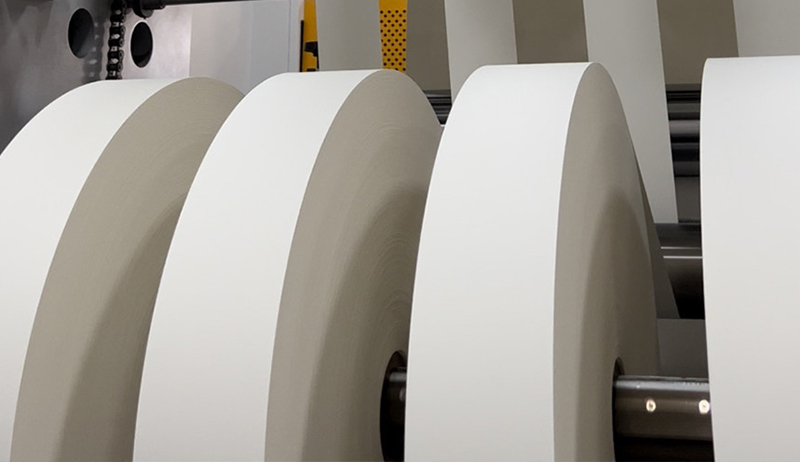

¿Qué es? Cartón Kraft Revestido ?

Cartón Kraft Revestido is a high-strength paperboard made from long-fiber kraft pulp, treated with a surface coating to enhance its barrier properties, printability, and durability. The coating—often clay-based, or via bio-coatings such as PLA (polylactic acid)—creates a smooth, uniform surface that supports high-quality printing and reliable moisture or grease resistance. :contentReference[oaicite:0]{index=0}

This coating process enables the paperboard to retain the natural toughness of kraft fiber while gaining enhanced functional characteristics like water resistance, oil resistance, tear strength, and improved aesthetics. As a result, coated kraft paperboard is widely used for food packaging, disposable containers, consumer goods packaging, and other applications demanding both robustness and good appearance. :contentReference[oaicite:1]{index=1}

- Fuerte estructura de base de pulpa kraft virgen: alta resistencia al desgarro y al estallido

- Recubrimiento de superficie (arcilla/PLA) para propiedades de barrera y superficie de impresión suave

- Compatibilidad con impresión flexográfica y offset: gráficos vibrantes y texto nítido

- Versatilidad en acabados: una cara, doble cara, cortes personalizados, rollos o láminas

Ventajas clave del cartón kraft revestido

Coated kraft paperboard’s blend of strength, barrier properties, and print quality make it a top choice for brands and manufacturers seeking reliable packaging materials. Because of its robust fiber structure and coated surface, it performs well in scenarios where standard paperboard might fail — such as exposure to moisture, grease, or rough handling during distribution. :contentReference[oaicite:2]{index=2}

Rendimiento de la barrera: resistencia al agua, al aceite y a la humedad

With coatings such as PLA or water-based sealants, coated kraft paperboard exhibits high resistance to water and oil penetration — a vital trait for food packaging, takeaway containers, and industrial packaging. The barrier helps preserve product freshness, prevent leakages, and maintain structural integrity even under humid or variable environmental conditions. :contentReference[oaicite:3]{index=3}

Durabilidad y resistencia al desgarro

The inherent strength of kraft fibers — long and tough — means that even after coating and finishing, coated kraft paperboard retains excellent tear resistance, burst strength, and puncture resistance. This makes it suitable for heavy-duty packaging, shipment cartons, and containers that must endure repeated handling without failure. :contentReference[oaicite:4]{index=4}

Calidad de impresión y flexibilidad estética

Because of its smooth coated surface, coated kraft paperboard supports high-resolution printing, vibrant color rendering, and detailed graphics. That makes it ideal for retail packaging, brand-sensitive goods, and premium products where visual appeal matters. Flexographic and other coating-compatible printing methods produce crisp images and consistent color — a major advantage for packaging designers. :contentReference[oaicite:5]{index=5}

Aplicaciones del cartón kraft revestido en todas las industrias

Thanks to its balanced mix of strength, barrier performance, and print compatibility, coated kraft paperboard finds applications in multiple fields — from food packaging to consumer goods, and industrial shipping. It’s especially popular for disposable food containers, takeaway packaging, paper bowls, grocery bags, gift boxes, and rigid carton boxes. :contentReference[oaicite:6]{index=6}

- Envases de alimentos: loncheras desechables, tazones de papel, recipientes para llevar

- Bienes de consumo: cajas de cosméticos, embalajes de electrónica ligera, cajas de venta al por menor.

- Industria y envío: cajas de cartón de alta resistencia, láminas en capas, capas de protección de productos

- Envases ecológicos y biodegradables: uso de PLA o recubrimientos a base de agua para reducir el uso de plástico

Cómo elegir la calidad adecuada de cartón kraft revestido

Not all coated kraft paperboards are created equal. Selection depends on intended use — whether food packaging requiring waterproof and grease-resistant surfaces, or retail packaging prioritizing print quality and stiffness. When evaluating options, consider coating type (PLA, PE, water-based), board weight (gsm), surface smoothness, and compliance with safety or environmental standards. :contentReference[oaicite:7]{index=7}

Comparación de tipos de revestimiento comunes

| Tipo de revestimiento | Principales beneficios | Casos de uso típicos |

| Recubrimiento PLA | Biodegradable, compostable, resistente al agua y al aceite, ecológico | Envases de alimentos, envases desechables, marcas ecológicas. |

| Recubrimiento a base de agua | Menores emisiones de COV, buena superficie de impresión, barrera moderada | Cajas de venta al por menor, embalajes impresos, productos de gama media. |

| PE/recubrimiento de plástico | Fuerte barrera contra la humedad y la grasa, alta durabilidad | Embalajes industriales, cajas de cartón resistentes, productos sensibles a la humedad. |

Consideraciones para envases sostenibles y de calidad alimentaria

For applications involving food or human contact, selecting coatings and base papers that meet safety and environmental standards is critical. PLA-coated paperboard is increasingly preferred because it combines compostability with functional performance. It meets many regulatory requirements for food-contact packaging and aligns with growing consumer demand for sustainable materials. :contentReference[oaicite:8]{index=8}

Preguntas frecuentes

¿El cartón kraft revestido es seguro para el envasado de alimentos?

Yes. When produced to food-grade standards, coated kraft paperboard — especially with PLA or water-based coatings — can safely contact food. The coatings create a moisture and oil barrier, preventing contamination and ensuring hygiene, while the kraft base provides structural strength. :contentReference[oaicite:9]{index=9}

¿Puede el cartón kraft revestido sustituir los envases de plástico?

Absolutely. Many modern coating technologies (PLA, water-based) provide moisture and grease resistance comparable to plastic, while offering better recyclability or compostability. As environmental regulations tighten, coated kraft paperboard becomes a viable, eco-conscious alternative to traditional plastic-lined packaging. :contentReference[oaicite:10]{index=10}

¿Qué durabilidad tiene el cartón kraft revestido bajo cargas pesadas o manipulación brusca?

Coated kraft paperboard retains much of the original strength of kraft fiber, including high tear resistance, puncture resistance, and burst strength. With proper coating and appropriate board weight (e.g. 200–350 gsm or more), it handles heavy-duty packaging, shipping, and industrial applications reliably. :contentReference[oaicite:11]{index=11}

¿El cartón kraft revestido es ecológico?

Yes, particularly when coated with biodegradable materials like PLA or using water-based coatings. The base kraft paper is usually derived from sustainably managed forests and remains recyclable and biodegradable. Many coated kraft paperboards now align with circular-economy principles and meet environmental certification standards. :contentReference[oaicite:12]{index=12}

¿Qué calidad de impresión se puede conseguir en cartón kraft estucado?

The smooth coated surface supports high-resolution flexographic or offset printing, enabling vibrant colors, fine details, and consistent branding. This makes coated kraft paperboard suitable for retail-grade and premium packaging where appearance matters. :contentReference[oaicite:13]{index=13}

English

English Español

Español